Daily Pre-Operation Inspections for All-Terrain Forklifts

Conducting a Thorough Walk-Around Inspection

Start every workday by walking around the all terrain forklift doing a full circle check. Look closely at the tires for signs of uneven wear patterns or bits of gravel stuck in them that might make things slippery when working on dirt or gravel pads. Take a good look at both the mast area and underneath the machine too. Structural cracks and those pesky hydraulic fluid leaks are real troublemakers responsible for nearly 4 out of 10 equipment failures according to Industrial Equipment Journal last year. Don't forget to inspect the forks and chains as well. If they look bent or warped past what the factory specs allow, that's a big red flag. Safety goes right out the window when these parts aren't within spec during lifts.

Checking Oil, Hydraulic Fluid, and Coolant Levels

It's important to check engine oil thickness every day, particularly when temps soar past 100 degrees Fahrenheit or plunge below freezing point, just to make sure everything stays properly lubricated. When it comes to hydraulic fluid levels, look through those sight glasses or pull out the dipstick as per what the specs say for starting up cold engines. And don't forget about coolant either. Take a peek at that expansion tank once the motor has warmed up to normal running temp. Getting this wrong actually causes around 27 percent of all shutdowns due to overheating problems in machines working on tough ground conditions. That kind of maintenance oversight can really cost time and money in field operations.

Verifying Functionality of Lights, Horns, and Safety Alarms

Before operating equipment in those dark corners of construction zones or dense forest areas where visibility drops off completely, workers should test their lighting systems thoroughly. The horn needs to reach around 97 decibels according to ANSI standards so operators can actually hear it above all that background machinery roar. Make sure those backup warning signals kick in automatically whenever the vehicle goes into reverse mode. Also check that emergency stops really do shut down everything right away when activated. Don't forget to swap out any damaged lens covers too since cracks let water seep inside and eventually ruin sensitive electronics over time.

Critical Component Maintenance: Tires, Undercarriage, and Steering Systems

Inspecting Off-Road Tires for Wear and Maintaining Proper Pressure

Proper tire maintenance matters a lot for all terrain forklifts working on rough ground or bumpy surfaces. Every day, workers need to look at the sides of the tires for damage, check how much tread remains (time to replace when it drops below 8mm mark) and watch out for any strange wearing patterns. Keeping air pressure right according to what the maker suggests usually falls between 30 and 45 psi. When tires are too low on air, the sides get stressed out easily. But pumping them up too much makes them lose grip on the ground. According to some research from last year in the industrial equipment field, folks who kept an eye on their tire pressure every week ended up spending about 19 percent less money replacing tires than those who only checked once a month.

Assessing Axles, Drive Train, and Suspension in Rough Terrain

Driving over rough ground really takes a toll on those important parts of the driveline system. Every time the machine hits around 50 hours of operation, take a good look at the axle seals to check for any oil leaks, make sure none of the grease fittings are clogged, and examine the suspension mounts for signs of cracking. Don't forget to go through all the bolts and nuts too. They need tightening according to manufacturer specs so everything stays properly aligned. The universal joints deserve special attention as well. If there's noticeable movement beyond what should be normal, that's a red flag pointing toward possible drivetrain problems down the road. When this happens, getting professional service right away becomes absolutely essential before bigger issues develop.

Diagnosing and Servicing Steering Drift and Linkage Wear

When steering drift goes beyond 10% of normal wheel rotation, it's time to stop what we're doing and take a closer look. Start by running a simple straight line test on flat terrain. If the forklift starts drifting off course without any driver input, there are several possible issues to check out. First, inspect those kingpins for wear signs. They need replacing when there's more than 3 degrees of rotational play. Also look at the tie rod ends for damage indicators like torn boot seals around them. And don't forget to check hydraulic pressure levels which should stay above 1500 psi even when idling. For maintenance purposes, make sure to apply fresh extreme pressure lithium grease to all steering linkage points approximately every hundred operating hours. This particular grease works well across temperature extremes from minus 40 degrees Fahrenheit right up to 300 degrees Fahrenheit, keeping everything responsive despite tough working conditions.

Hydraulic and Brake System Integrity in Harsh Environments

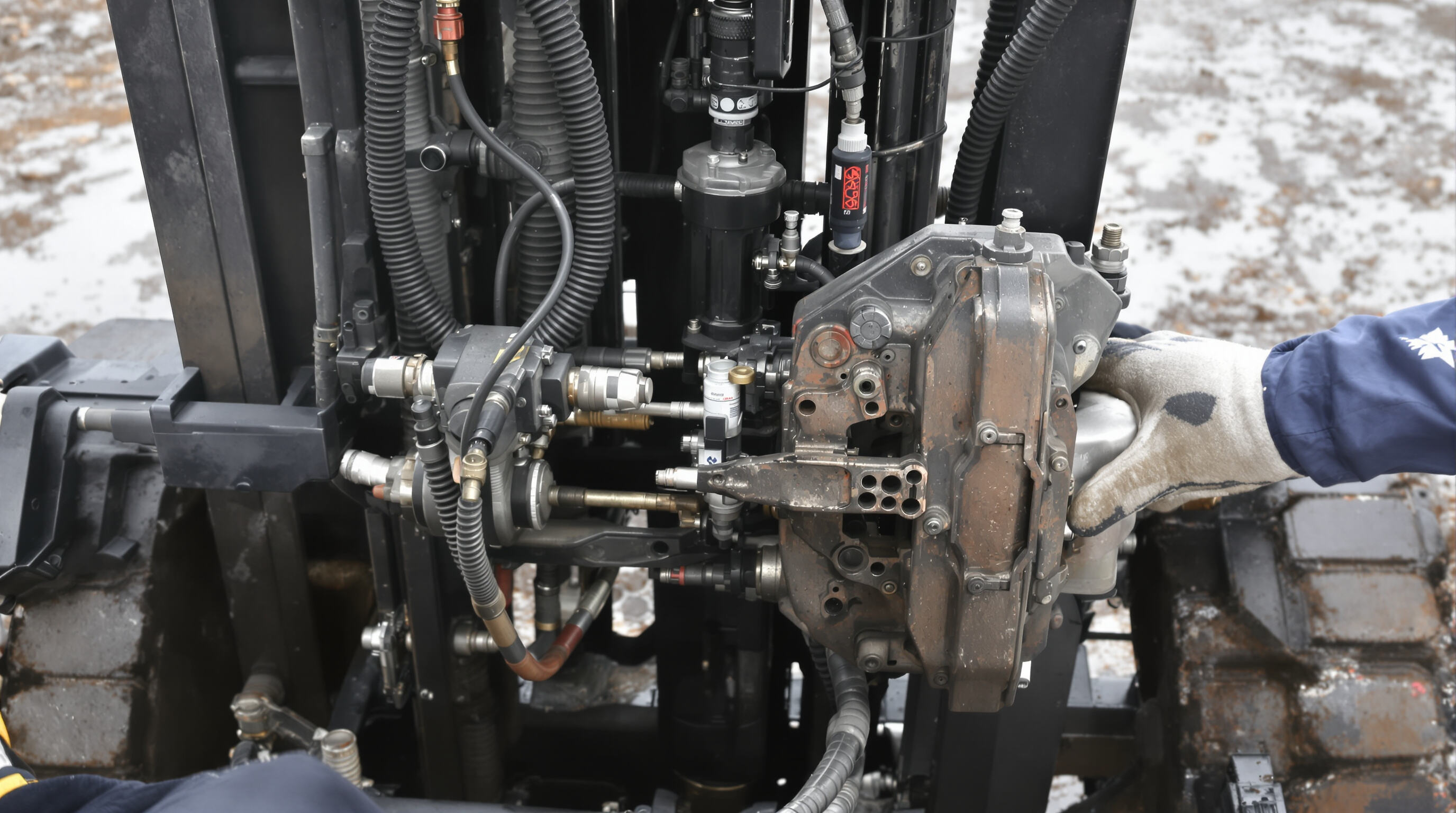

Preventing Hydraulic Leaks and Contamination in Extreme Conditions

Regular checks on hydraulic lines and fittings can cut down equipment failures by almost 40% when working off road according to the Machinery Reliability Report from 2023. For extreme temperatures, synthetic seals that work between minus 40 degrees Fahrenheit up to 250 degrees are recommended. Also important is putting in place those 10 micron inline filters since they stop tiny particles getting through. These small bits of debris actually cause around three quarters of all problems with hydraulics systems. When transferring fluids, maintaining cleanliness matters too. Workers should wear gloves while servicing reservoirs to keep out dirt and moisture that could ruin the whole system over time.

Maintaining Hydraulic Performance Across Temperature Extremes

For consistent performance when temperatures swing around, tri shield hydraulic fluids with those special anti foaming additives work wonders. These fluids keep flowing properly about 22 percent longer compared to regular mineral oils when going through temperature changes. When dealing with really hot conditions above 140 degrees Fahrenheit, it makes sense to combine these improved viscosity index fluids with some sort of cooler system on the side. This helps avoid problems like cavitation and damaged seals that can happen in extreme heat. Looking at actual field reports, equipment with built in thermal management systems ends up needing replacement parts roughly 30 percent less frequently after running for 5,000 service hours straight. Makes a big difference in maintenance costs over time.

Ensuring Reliable Braking on Wet, Icy, and Inclined Surfaces

Getting reliable stops matters a lot when roads get slick or hilly. Brake pads made with non-slip compounds can cut stopping distance almost half on slopes at 15 degrees where there's about quarter inch of standing water according to ISO 3450 from 2022. Check brake fluid for moisture once a month with those test strips everyone carries around these days. If the fluid has just 3% water in it, corrosion inside ABS valves happens twice as fast. When temperatures drop below twenty degrees Fahrenheit, look for parking brakes that meet EN 12530 standards. These systems have special shoes with carbide grit built right in so they still grip properly even when ice forms a smooth glaze over surfaces.

Implementing Proactive Preventive Maintenance Programs

Developing a Scheduled Maintenance Plan to Reduce Downtime

Good preventive maintenance begins by creating a schedule that matches what the equipment maker recommends plus considers how hard the machinery actually works day to day. According to Material Handling Equipment Insights from last year, companies that implement computerized maintenance management systems experience about 18 percent fewer unexpected breakdowns compared to places that wait until something breaks before fixing it. When checking equipment, focus extra attention on parts that take the most punishment over time such as hydraulic pumps, those little roller things on masts, and brake calipers. These should be inspected regularly depending on how much they're used. Don't forget to apply lubricant to all those moving joints at least once every 200 operating hours. This helps stop rust formation, which becomes really important for facilities located near coastlines where salty air accelerates metal degradation.

Aligning Maintenance Practices with OSHA and ANSI Compliance Standards

Following OSHA 1910.178 and ANSI/ITSDF B56.6 regulations isn't just good practice it's absolutely necessary for worker safety and avoiding costly fines down the road. Make sure those annual load capacity tests get documented properly, and don't forget to check the structural integrity of those rollover protective structures (ROPS) after around 2,500 service hours. Operators working in cold storage facilities need special attention too. The ANSI -20 degree Celsius standards exist for a reason when temps drop, hydraulic systems can fail if not maintained correctly, and fluid viscosity changes dramatically in freezing conditions which affects performance and safety alike.

Balancing Maintenance Investment Against Cost of Equipment Failure

Studies show that getting ahead of equipment problems can cut down on repair costs by around 34%, which translates to about $42k saved each year for every mining machine according to research from the Ponemon Institute back in 2023. When looking at spending money on things like automatic greasing systems that typically range between three thousand two hundred and seven thousand five hundred dollars, it's worth comparing those numbers to what happens when drive axles fail completely. Fixing those failures alone costs eighteen grand just for repairs, not counting all the lost productivity time that adds up at roughly five hundred eighty dollars per hour downtime. For tougher environments where machines really get worked hard, installing predictive maintenance gear such as vibration sensors at about one thousand eight hundred per unit makes sense too. These little gadgets actually help transmissions last anywhere from two to three extra years, giving companies roughly nine times their money back after seven full years of operation.

Overcoming Environmental Challenges: Cold Weather and Adverse Conditions

All-terrain forklifts operating in harsh environments require targeted maintenance strategies to counteract temperature extremes and moisture exposure. Leading manufacturers recommend weather-specific protocols to manage operational stresses from snow, ice, and heavy rainfall.

Cold Weather Operation: Managing Snow, Ice, and Rain Impacts

Warming up hydraulic systems before they kick into action makes all the difference when temps drop below freezing, cutting down system failures by about 34% according to a study published last year in Industrial Equipment Journal. For anyone working in cold climates, clearing off ice buildup matters a lot. Grab those plastic scrapers for tires and brakes instead of metal ones that might scratch things. Wrap insulation around battery connections too. And don't forget to switch to thinner fluids designed for temperatures as low as minus 25 degrees Celsius. Checking tire treads every day along with air pressure isn't just routine maintenance it's actually what keeps vehicles from slipping around on roads covered in ice or rainwater. Some operators swear by these steps after experiencing firsthand what happens when shortcuts are taken during winter operations.

Protecting Systems from Moisture and Corrosion in Wet Conditions

Give those undercarriage parts a good cleaning once a week to get rid of all that road salt and mineral buildup that eats away at metal. For the moving parts, slap on some water displacing lubricant that's been approved by NSF standards. This helps stop rust from forming and keeps everything moving smoothly when needed. Shops that regularly use zinc rich primer on their steel structures, apply dielectric grease to electrical contacts, and blast out moisture with compressed air after crossing through deep puddles have seen their parts last almost twice as long according to maintenance reports. The difference is pretty significant for fleet managers looking to stretch their equipment budgets further between replacements.

FAQ

Why is tire maintenance crucial for all-terrain forklifts?

Tire maintenance is important because improper tire pressure and tread can lead to equipment failure or unsafe working conditions, especially on rough or slippery surfaces.

How can hydraulic system failures be avoided?

Regular checks and the use of synthetic seals and inline filters can prevent hydraulic leaks and contamination, thus reducing equipment failures.

What should be considered in cold weather operation?

Warming up hydraulic systems and using suitable fluids designed for low temperatures is essential to prevent failures. Clearing ice and ensuring proper tire tread and pressure are also necessary.

Table of Contents

- Daily Pre-Operation Inspections for All-Terrain Forklifts

- Critical Component Maintenance: Tires, Undercarriage, and Steering Systems

- Hydraulic and Brake System Integrity in Harsh Environments

- Implementing Proactive Preventive Maintenance Programs

- Overcoming Environmental Challenges: Cold Weather and Adverse Conditions

- FAQ